In FTTx and PON architectures, optical spliter plays an increasingly significant role to create a variety ofpoint-to-multipoint filber optic networks. But do you know what is a fiber optic splitter? in fact, a fiber opticspliter is a passive optical device that can split or separate an incident light beam into two or more lightbeams. Basically, there are two types of fiber splitter classified by their working principle: fused biconicaltaper splitter (FBT splitter) and planar lightwave circuit splitter (PLC splitter). You may have one question :what's the difference between them and shall we use FBT or PLC splitter?

What is FBT Splitter?

FBT splitter is based on traditional technology, which is a kind of Passive Network Tap, involving the fusion of several fibers from the side of each fiber. The fibers are aligned by heating them at a specific location and length. Due to the fragility of the fused fibers, they are protected by a glass tube made of epoxy and silica powder. Subsequently, a stainless steel tube covers the inner glass tube and is sealed with silicon. As technology continues to develop, the quality of FBT splitters has significantly improved, making them a cost-effective solution. The following table outlines the advantages and disadvantages of FBT splitters.

| Advantages | Disadvantages |

|---|---|

| Cost-Effective | Higher Insertion Loss |

| Generally less expensive to manufacture | Can affect overall system performance |

| Compact Size | Wavelength Dependency |

| Easier installation in tight spaces | Performance may vary across wavelengths |

| Simplicity | Limited Scalability |

| Straightforward manufacturing process | More challenging to scale for many outputs |

| Flexibility in Splitting Ratios | Less Reliable Performance |

| Can be designed for various ratios | May not provide consistent performance |

| Good Performance for Short Distances | Temperature Sensitivity |

| Effective in short-distance applications | Performance can be affected by temperature fluctuations |

What is PLC Splitter?

PLC splitter is based on planar lightwave circuit technology, which is a kind of Passive Network Tap. It comprises three layers: a substrate, a waveguide, and a lid. The waveguide plays a key role in the splitting process which allows for passing specific percentages of light. So the signal can be split equally. In addition, PLC splitters are available in a variety of split ratios, including 1:4, 1:8, 1:16, 1:32, 1:64, etc. They also have several types, such as bare PLC splitter, blockless PLC splitter, fanout PLC splitter, mini plug-in type PLC splitter, etc. You also can check the article How Much Do You Know About PLC Splitter? for more information about PLC splitter. The following table shows the advantages and disadvantages of PLC splitter.

| Advantages | Disadvantages |

|---|---|

| Low Insertion Loss | Higher Cost |

| Typically offers lower signal loss | Generally more expensive to manufacture |

| Broad Wavelength Performance | Larger Size |

| Performs consistently across multiple wavelengths | Usually bulkier than FBT splitters |

| High Reliability | Complex Manufacturing Process |

| Provides consistent performance over long distances | More complex to produce compared to FBT splitters |

| Flexible Splitting Ratios | Initial Setup Complexity |

| Available in various configurations (e.g., 1xN) | May require more careful installation and configuration |

| Temperature Stability | Potential Fragility |

| Better performance across temperature variations | More sensitive to physical damage |

FBT Splitter vs PLC Splitter: What Are the Differences? (To know more about What’s the difference between Passive Network Tap and Active Network Tap?)

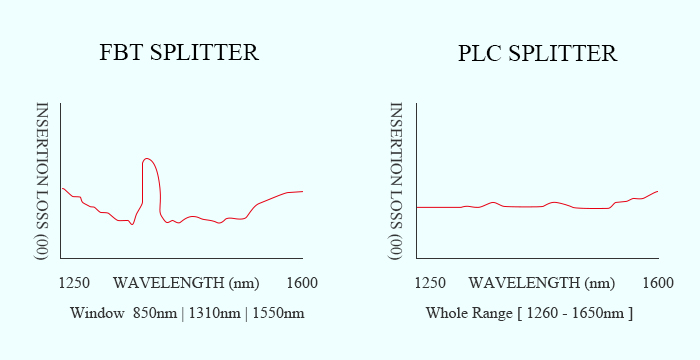

1. Operating Wavelength

FBT splitter only supports three wavelengths: 850nm, 1310nm, and 1550nm, which makes its inability to work on other wavelengths. The PLC splitter can support wavelengths from 1260 to 1650nm. The adjustable range of wavelength makes PLC splitter suitable for more applications.

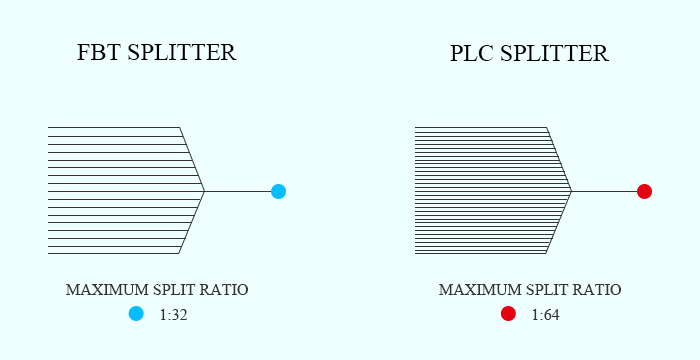

2. Splitting Ratio

Splitting ratio is decided by the inputs and outputs of an optical cable splitter. The maximum split ratio of FBT splitter is up to 1:32, which means one or two inputs can be split into an output maximum of 32 fibers at a time. However, the split ratio of PLC splitter is up to 1:64 - one or two inputs with an output maximum of 64 fibers. Besides, FBT splitter is customizable, and the special types are 1:3, 1:7, 1:11, etc. But PLC splitter is non-customizable, and it has only standard versions like 1:2, 1:4, 1:8, 1:16, 1:32, and so on.

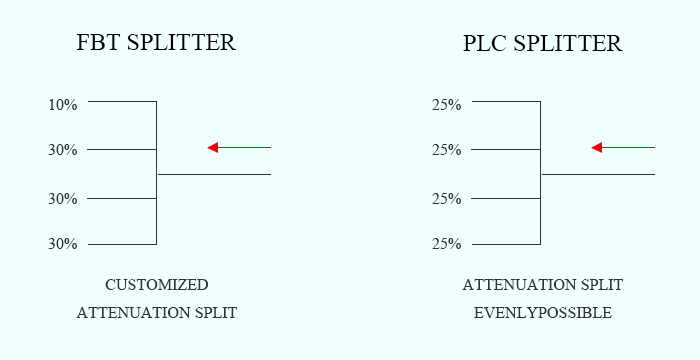

3. Splitting Uniformity

The signal processed by FBT splitters cannot be split evenly due to a lack of management of the signals, so its transmission distance can be affected. However, PLC splitter can support equal splitter ratios for all branches, which can ensure a more stable optical transmission.

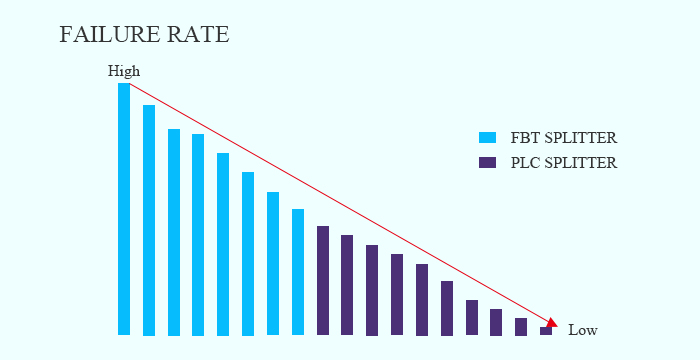

4. Failure Rate

FBT splitter is typically used for networks requiring the splitter configuration of less than 4 splits. The larger the split, the greater the failure rate. When its splitting ratio is larger than 1:8, more errors will occur and cause a higher failure rate. Thus, FBT splitter is more restricted to the number of splits in one coupling. But the failure rate of PLC splitter is much smaller.

5. Temperature-Dependent Loss

In certain areas, the temperature can be a crucial factor that affects the insertion loss of optical components. FBT splitter can work stable under the temperature of -5 to 75℃. PLC splitter can work at a wider temperature range of -40 to 85 ℃, providing relatively good performance in the areas of extreme climate.

6. Price

Owing to the complicated manufacturing technology of PLC splitter, its cost is generally higher than the FBT splitter. If your application is simple and short of funds, FBT splitter can provides a cost-effective solution. Nevertheless, the price gap between the two splitter types is narrowing as the demand for PLC splitters continues to rise.

7. Size

FBT splitters typically have a larger and bulkier design compared to PLC splitters. They demand more space and are better suited for applications where size is not a limiting factor. PLC splitters boast a compact form factor, making them easily integrable into small packages. They excel in applications with limited space, including inside patch panels or optical network terminals.

Post time: Nov-26-2024